5s Certification Process

Leaders must set the tone and lead by example.

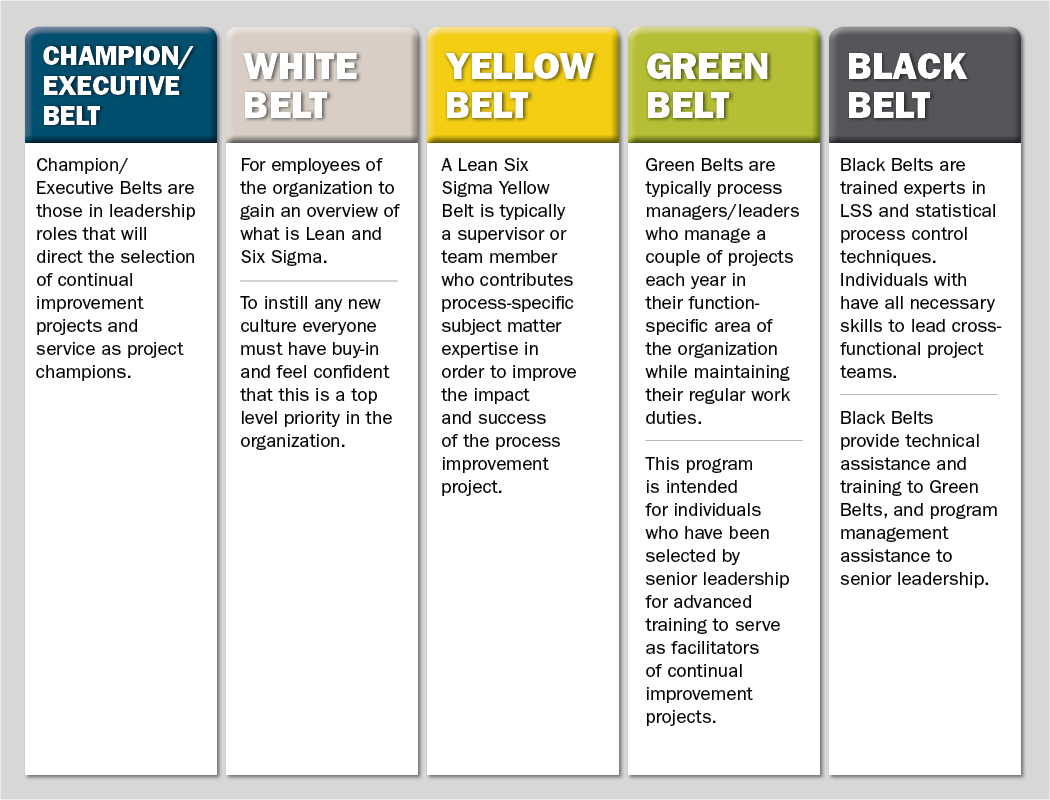

5s certification process. Roles in a 5s program are straightforward. In the 5s training single module youll learn the basics of these tools and techniques and continue building your problem solving muscles. Integrate the 5s methodology into the performance management system. No the 5s training course includes all of the course work required to study for and pass the final exam.

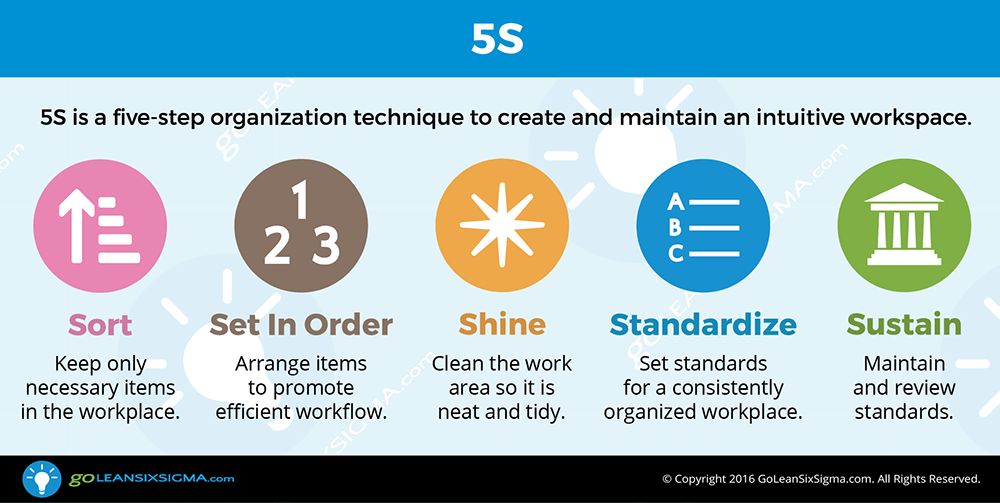

5s certification may be as informal as making your own award when your workplace first passes its internal 5s audit but it is an important component in having a complete and successful 5s environment. The term sort is originally derived from the japanese word seiri. 5s transactional assessment template example. 5s 5s consulting 5s training 5s support.

Is the 5s certification test difficult. You must have a basic understanding of the 5s principles so that you can accomplish tasks assigned by the 5s sponsor. If you are interested in learning more or having the process evaluation and improvement team facilitate a 5s exercise for your. Sort is the first step in any 5s process.

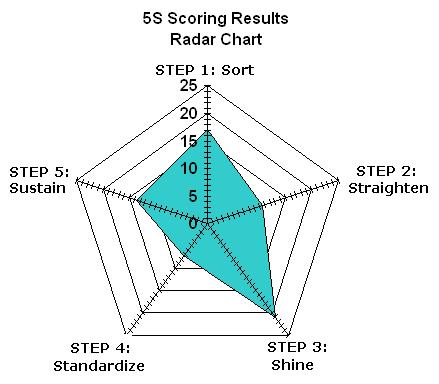

It is the most important step in that it addresses the need to perform 5s on a consistent and systematic basis. The output of engineering and design in a lean enterprise is information the theory behind using 5s here is dirty cluttered or damaged surfaces attract the eye which spends a fraction of a second trying to pull useful information from them every time we glance past. What youll get certificate pduscpes 5s manufacturing assessment template example. Each step in the 5s process has an associated goal that can be specifically outlined to help guide efforts.

Why you should register for 5s training certificate. This step in the 5s process can sometimes become the most challenging of all the five steps. 5s in lean product and process development. Build organizational commitment so that 5s becomes one of your organizational values so that everyone develops 5s as a habit.

5s digital planning board the wcm app. The certification process in lean 5s. The program should be a continuously evolving and growing improvement process. 5s methodology process evaluation improvement what is 5s.

You can start implementing 5s by providing training to your staff to understand the system. For the step of sort the goal is to remove unnecessary items from the room station or space being organized. The intent of the 5s method is to improve efficiency by eliminating waste. The certification audit programme of the the 5s institute is built round a thorough investigation of the institution and its way of working and the extent of its adoption of the 5ss viz seiri seiton seiso seiketsu shitsuke.

Sustaining is the continuation of the sort straighten shine and standardize steps.