Crude Oil Extraction Diagram

As with liquid oil the composition of natural gas varies from field to field.

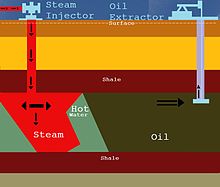

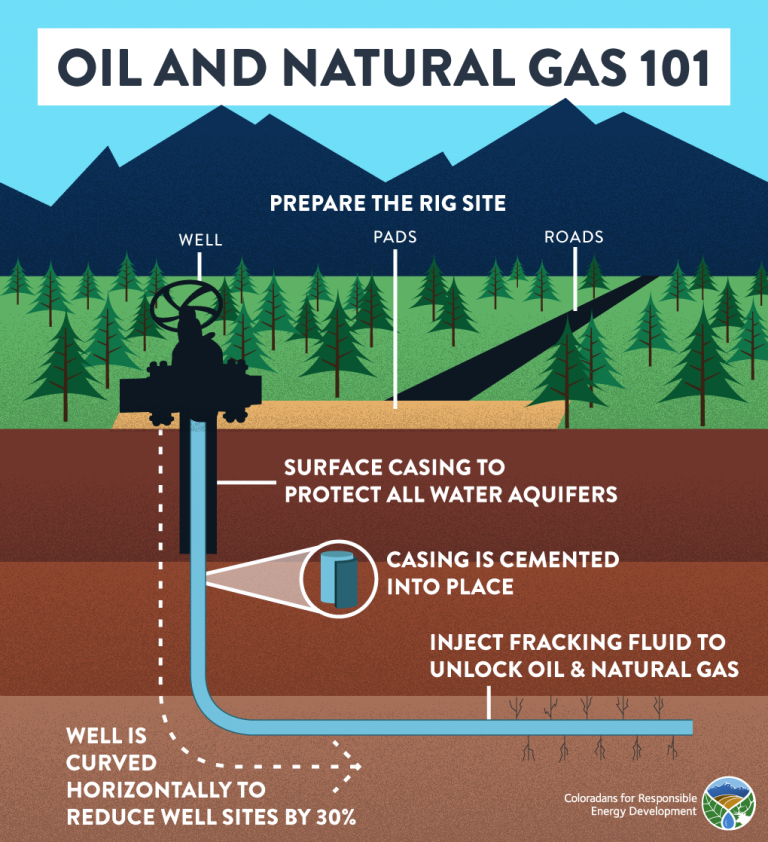

Crude oil extraction diagram. Tertiary recovery begins when secondary oil recovery is not enough to continue adequate extraction but only when the oil can still be extracted profitably. Since this technique only targets the oil which is either susceptible to its release or accessible to the pump jack this is very limited in its extraction potential. Crude oil extraction process. Typically this means pumping steam underground to melt the viscous stuff.

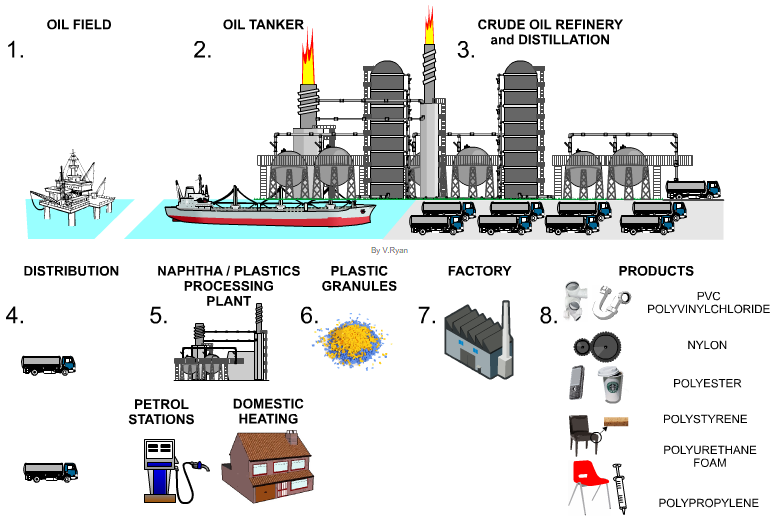

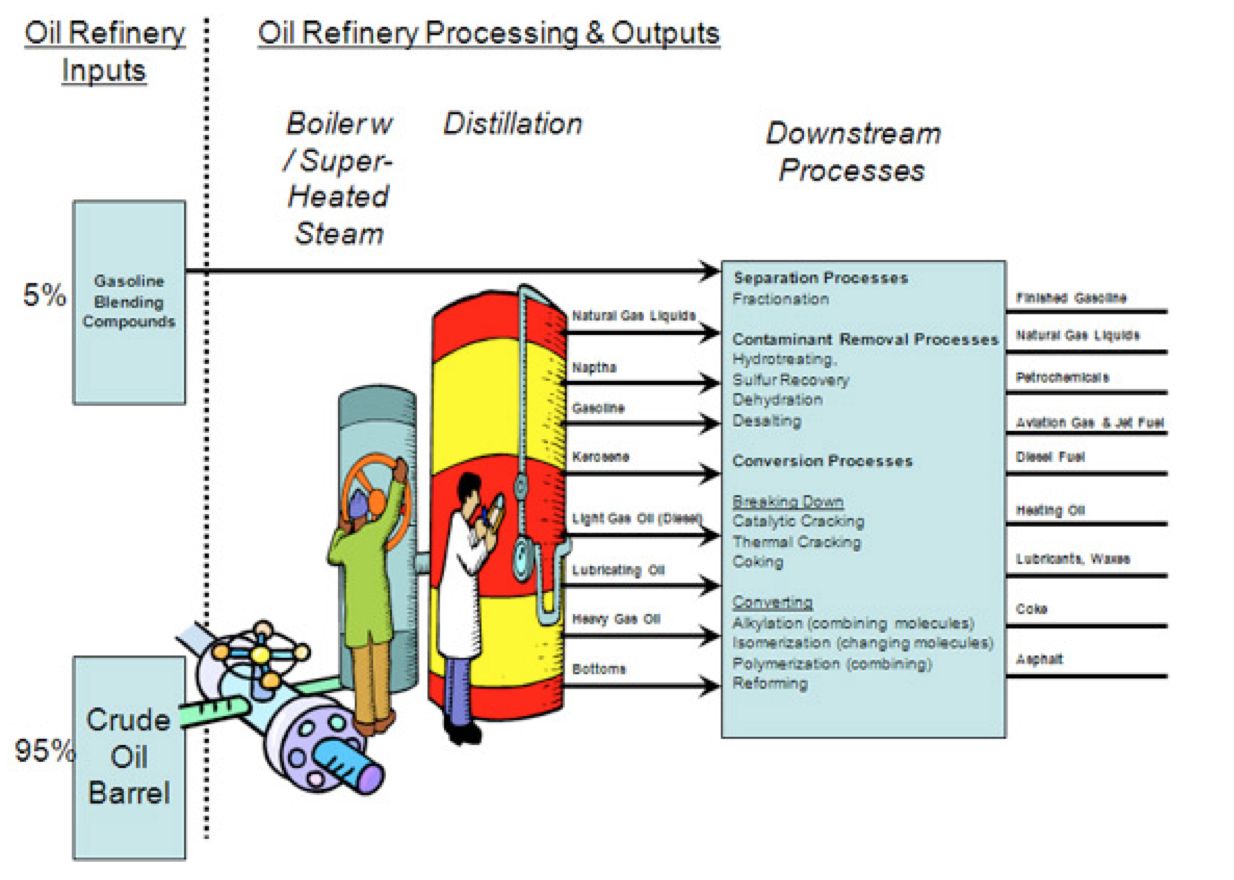

This is crude oil thats thicker or more viscous than regular light crude oil. For crude oil to be used effectively by modern industry it has to be separated into its component parts and have impurities like sulfur removed. Oilseed handlingelevator operations figure 9111 1 is a schematic diagram of a typical soybean handlingelevator operation that precedes the preparation of soybeans for the solvent extraction process. Natural gas is principally methane with smaller amounts of other alkanes ethane propane and the butanes.

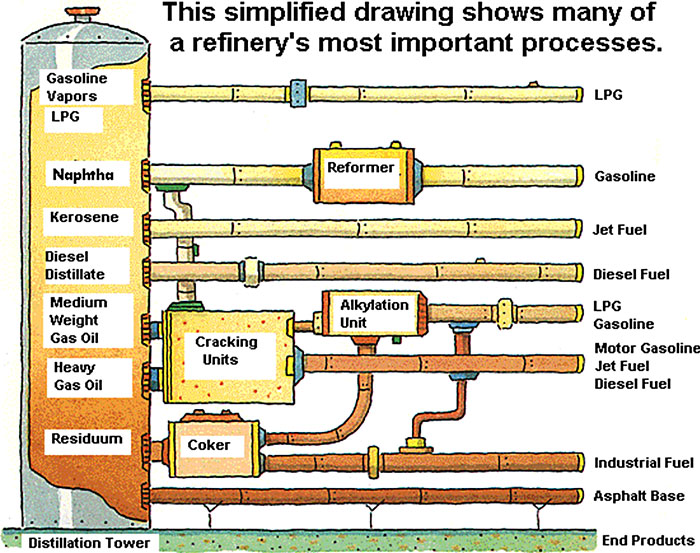

A steel pipe is placed inside the oil well for structural strength. The image below is a schematic flow diagram of a typical petroleum refinery that depicts the various refining processes and the flow of intermediate product streams that occurs between the inlet crude oil feedstock and the final end products. Crude oil distillation is more complicated than product distillation in part because crude oils contain water salts and suspended solids. This costs lots of water and energy to convert that water to steam.

In fact only around 5 15 of the wells potential are recovered from the primary method. When prices are high previously unprofitable wells are brought back into use and when they are low extraction is curtailed. This depends on the cost of the extraction method and the current price of crude oil. Soybeans for solvent extraction solvent extraction and oil desolventizing flake desolventizing and oil refining.

First a crude oil well is created by drilling a hole into the earth with an oil rig. In general united states prefers gasoline to diesel whereas the rest of the world prefers diesel to gasoline fccbased refineries will still produce a great deal of gasoline even when trying to maximize diesel production. In some areas there is preponderance of smaller hydrocarbon molecules light crude oil in heavy crude oil there is a greater proportion of larger molecules. Step 1 in the refining process is to remove these contaminants so as to reduce corrosion plugging and fouling of equipment and to prevent poisoning catalysts in processing units.

This involves heating crude oil to about 350 degrees celsius to turn it into a mixture of gases. That its thicker it doesnt easily flow out of a well requiring more work to extract. Before learning the costs components of crude oil extraction lets take a look at how producers extract crude oil from the ground.