How To Make Woodworking Templates

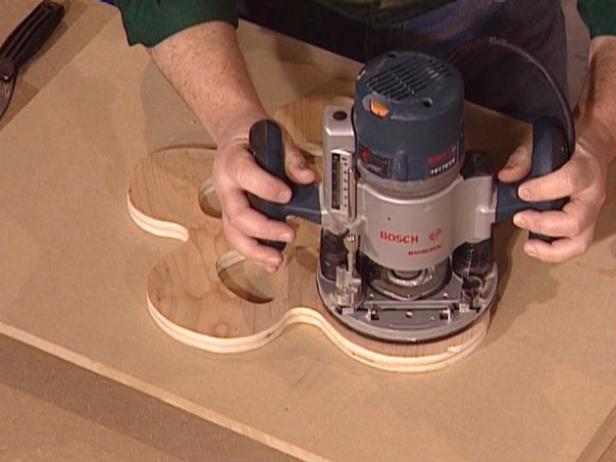

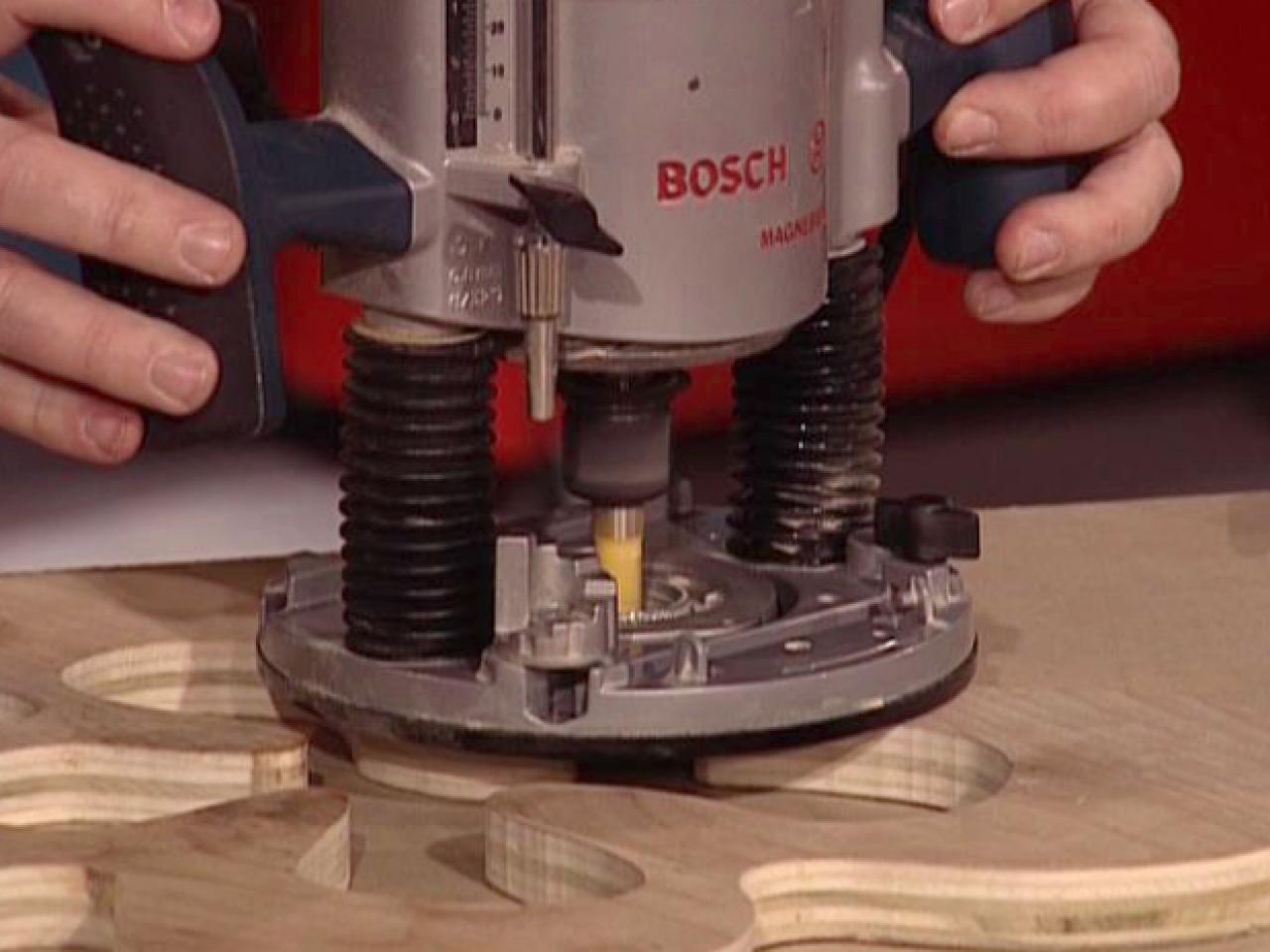

Router templates can be very simple to make and a quarter inch hardboard can be used and sanded to make a crisp clean and smooth template.

How to make woodworking templates. And now i can use a flush trim router bit to route the exact shape of the woodworking templates in the workpieces. It just takes too much time with these materials. I band sawed all the parts and hand sanded them into shape. I just finished making my granddaughter a childs rocker for her first christmas out of cherry wood.

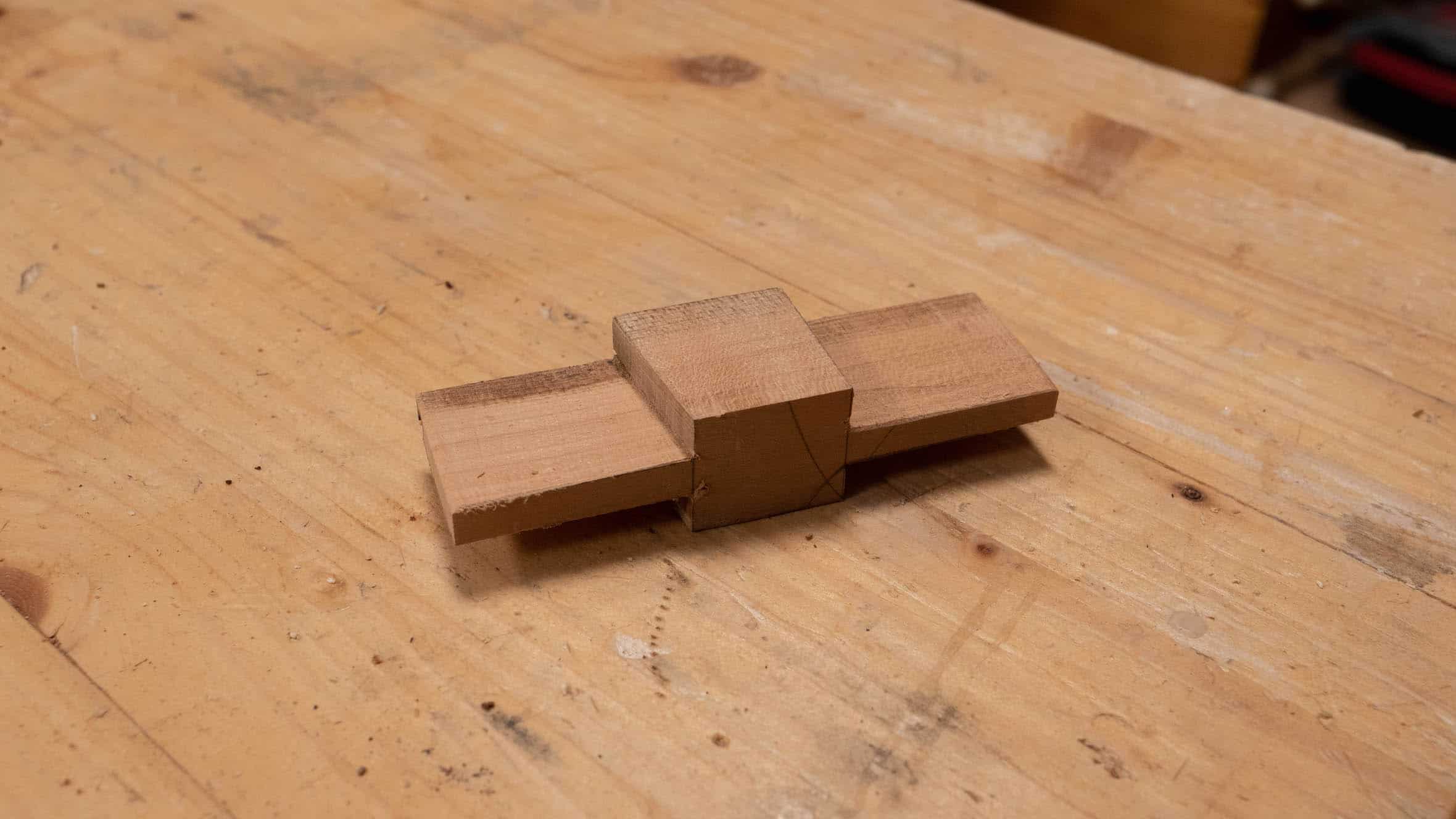

Just to make sure the woodworking template sticks well i have to press it against the workpiece. If i had to produce these templates using plywood or other wood and plastic products my use of full size templates would substantially diminish and id be less efficient in the shop. They they can set the scale to 11 make a pdf export and print that. All came out great.

If the user is using the pro version i suggest that the create a scene in sketchup and send it to layout. Learn about making l shaped templates with help from an. How do you make perfect. But now my next two projects will require making many multiple parts so the use of templates will work great.

You can however create profile templates from the sketchup model to help you shape the wood. Every so often i field questions about how to print full size patterns from sketchup models. But here is the problem. After youve worked through creating a complex shape in sketchup going to the shop to make it in wood can be another thing entirely.

You can turn a humble piece of hardboard into a template or pattern for a decorative design structural part geometric feature or any other shape. Woodworking template create a hard board pattern. Here is a helpful tip for making woodworking templates that you can use over and over again. I find thick poster board to be the best material.

As you make the template you can fuss over the details until theyre just right or toss it and start again.