Injection Molding Process Sheet Template

Even worse there is a different setup sheet for each different press the mold goes into.

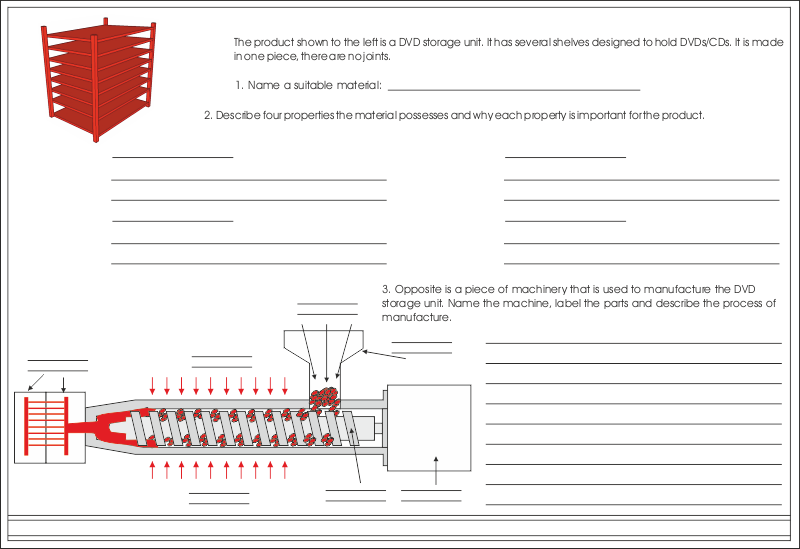

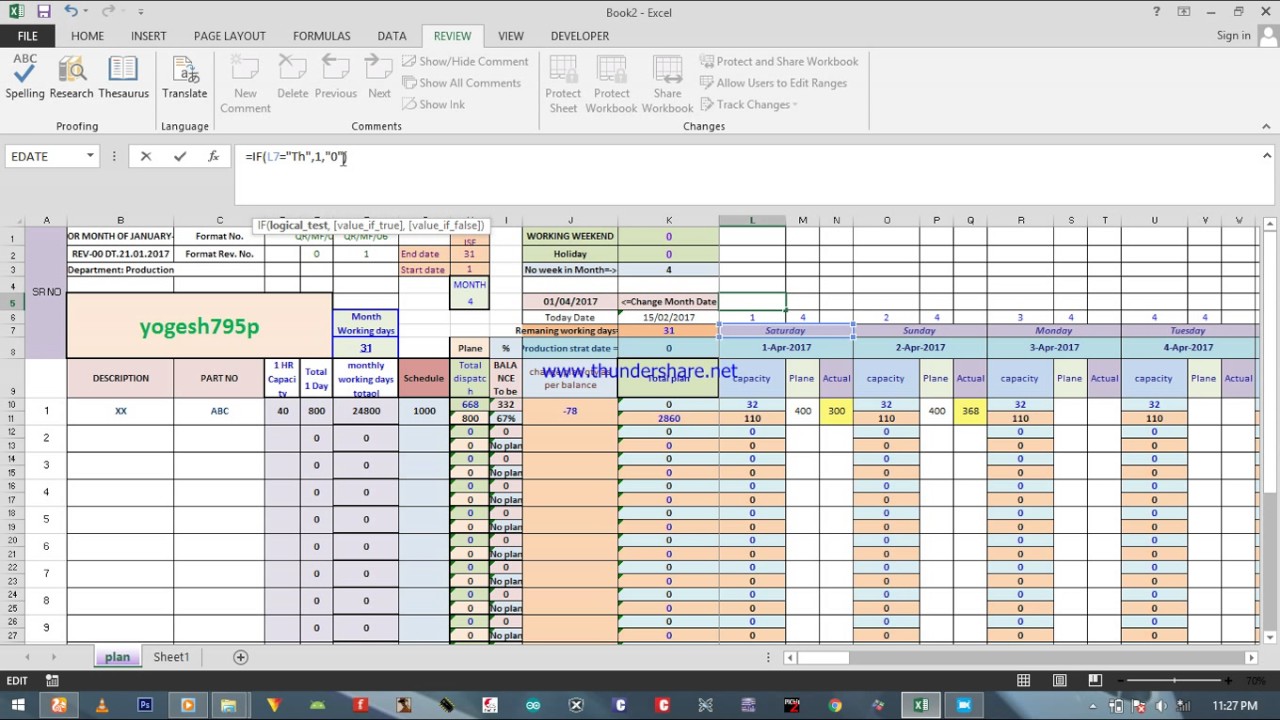

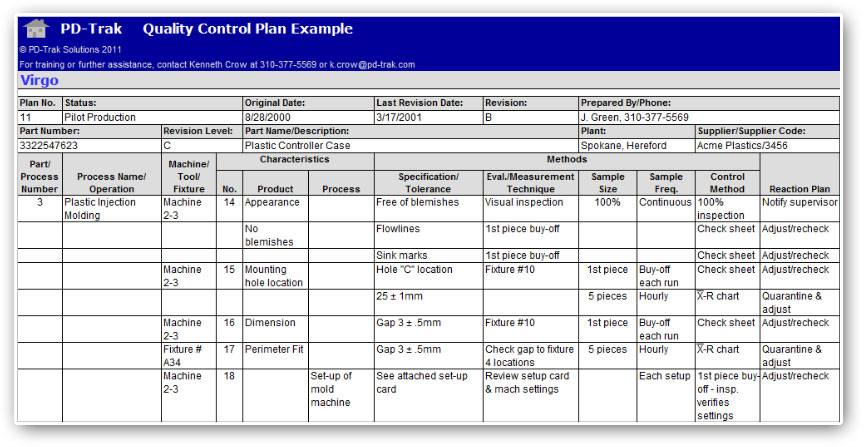

Injection molding process sheet template. There are different methods for making setup sheets for injection molding and various companies all have different approaches. Then the molding process begins. Arios gave good advice in this post. In process production test stations in pfmea process fmea making a process pfmea no dfmea non automotive toll manufacturer.

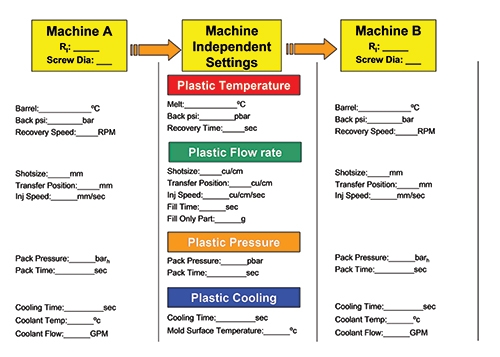

Documentation of the process is usually captured in what most call the machinemold setup sheet seems simple enough but if you visited the estimated 16000 molding shops in the us. Agreedear friends i already done costing process with our standard worksheet for plastic injection parts. The size and shape of the process window is determined by certain constraining boundaries. A simplified basic process parameter sheet could be beneficial to everyone that a given molding machine.

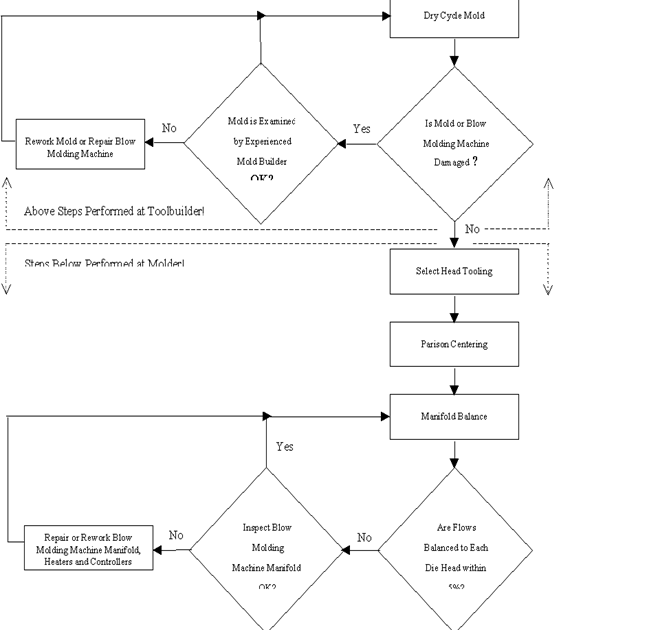

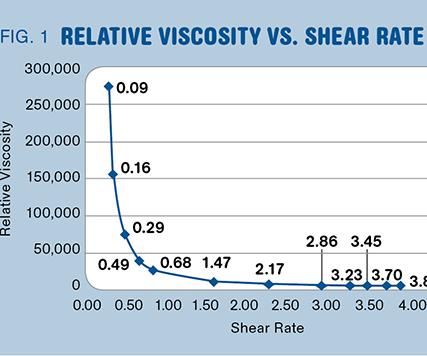

Injection molding process in terms of the injection velocity and pack pressure. Tooling is almost a project in and of itself and only one phase of the entire injection molding process. I am trying to help our molding manager develop a standard setup sheet for his production tooling. Check the two threads related to blowinjection molding in the similar discussions box below the page just scroll down the page.

Wo2006124200a1 jection molded preform stretch blow molding process sheet template setup. Mold processes for which c mold provides analyses include injection molding gas assisted injection molding reactive molding co injection molding blow molding and thermoforming. Injection molding process setup sheet template mold technician resume view. Injection molding process sheet template what we need for quotation of tooling or view.

Any body help me. I feel it is not carrying all processes material handling transport etc somthing missed. Processing setup sheet for injection molding process injection molding parameter units typical setting melt temperature 0f 450 460 nozzle 0f 440 450 adapter 0f 450 460 front 0f 450 470 middle 0f 440 460 rear 0f 430 450 hot runnermanifold temperature 0f 380 420 first or boost stage injection. At this time the process technician documents specific information on an injection mold layout iml sheet such as start date time starting technician and press number.

Potentially negative aspects of injection molding include the following. Interesting topic new aiag pfmea process excel template attached. Hi qualitybb i started a new thread for you. Please send any standard costing sheet available for plastic injection and.

Rockware corp injection molding process sheet setup view. Injection blow molding process evaluation. Pfmea process fmea can be common for 3000 products. Youd wind up with 16001 different setup sheets.

The default material properties and process conditions design templates provided in c mold process estimator for each of these mold processes are given below. Two of the major disadvantages to injection molding are the high tooling costs and large required lead times. The injection clamp and temperature profiles are the most important parameters and the most common screens on a machine controller. Here is a copy of a process parameter sheet ive used in the past and it helped standardize the process.

3 defines the combined upper. I need a checklist to audit the injection molding process. Any ideas where i could find these. Hello i am looking for standard plastic injection setup sheet templates.

After the process has stabilized a shot is checked and released by qa and the runrepair cycle is underway. Approach a is use sheets that replicate all of the machines.