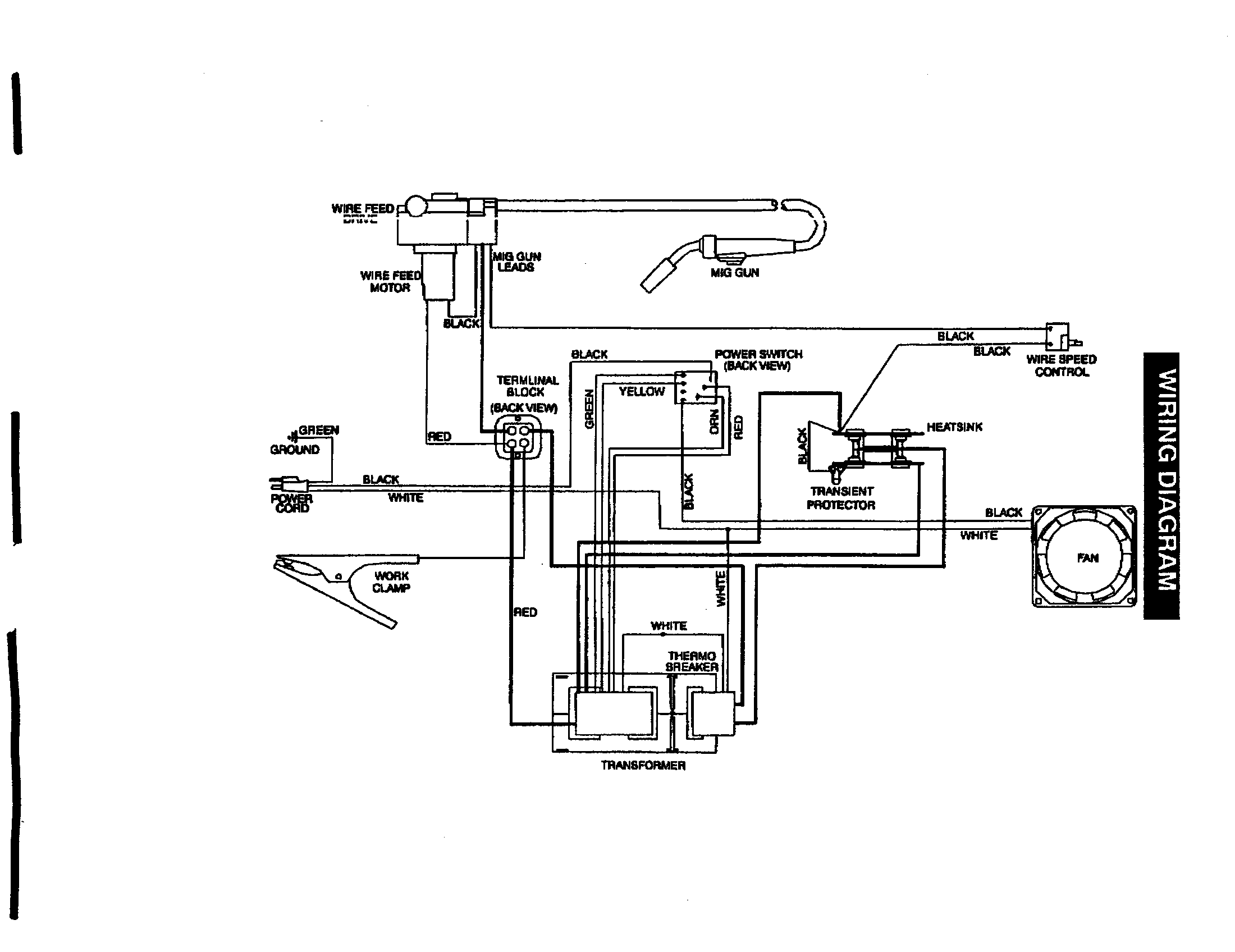

Mig Welder Diagram

Lincoln mig welder parts diagram thank you for visiting our website.

Mig welder diagram. It is a process developed in the 1940s and is considered semi automated. Each method has its own characteristic properties advantages and corresponding limitations. Mig welding is sometimes referred to as the hot glue gun of the weldi. Nowadays were pleased to declare we have found an incredibly interesting topic to be discussed namely lincoln mig welder parts diagram.

Some people trying to find details about lincoln mig welder parts diagram and of course one of them is you is. How to weld mig welding. Mig welding is the awesome process of using electricity to melt and join pieces of metal together. Please subscribe its free for.

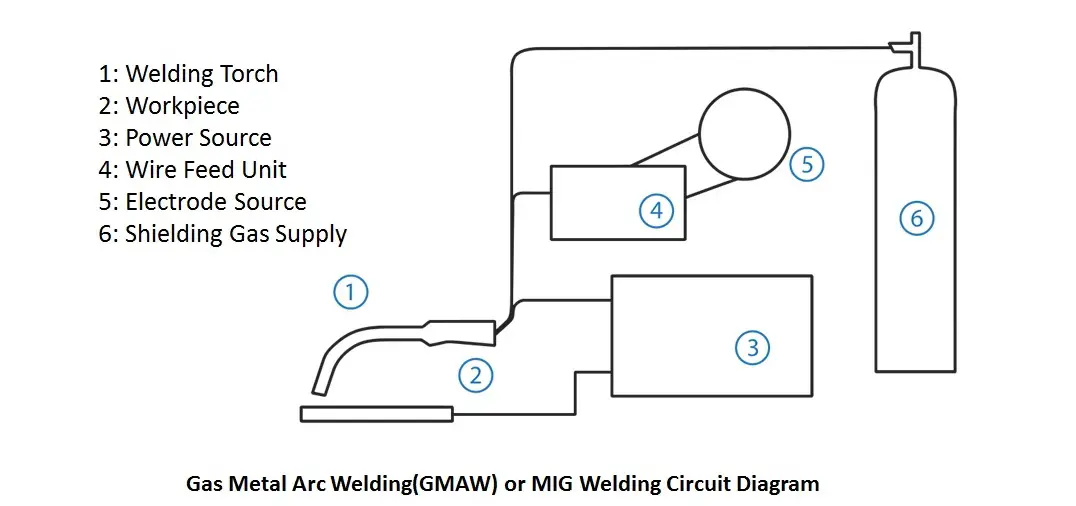

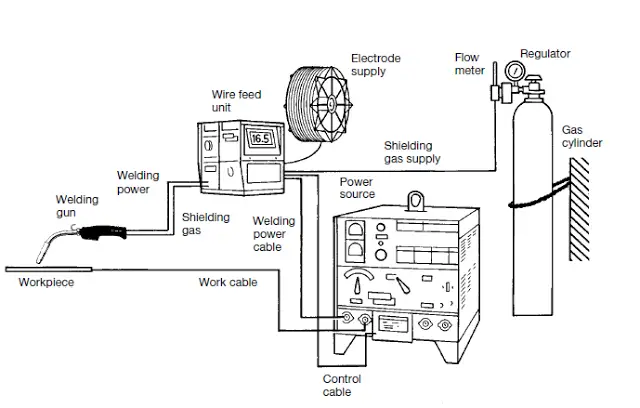

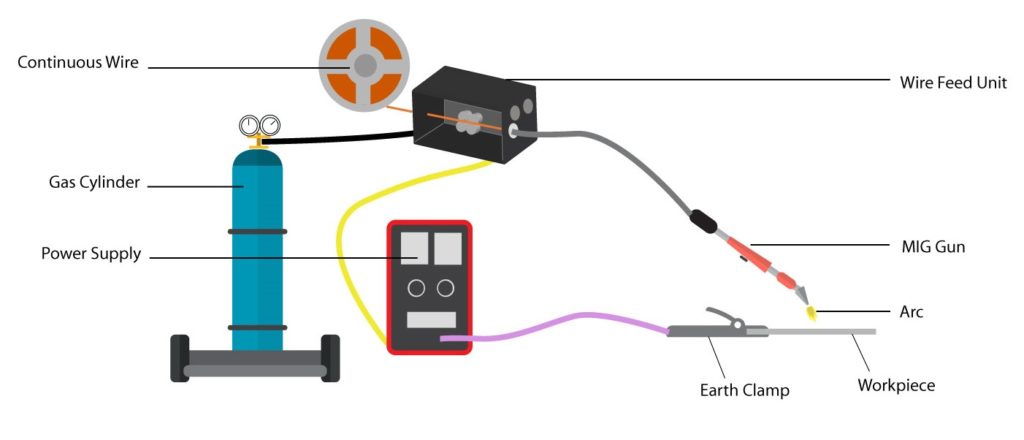

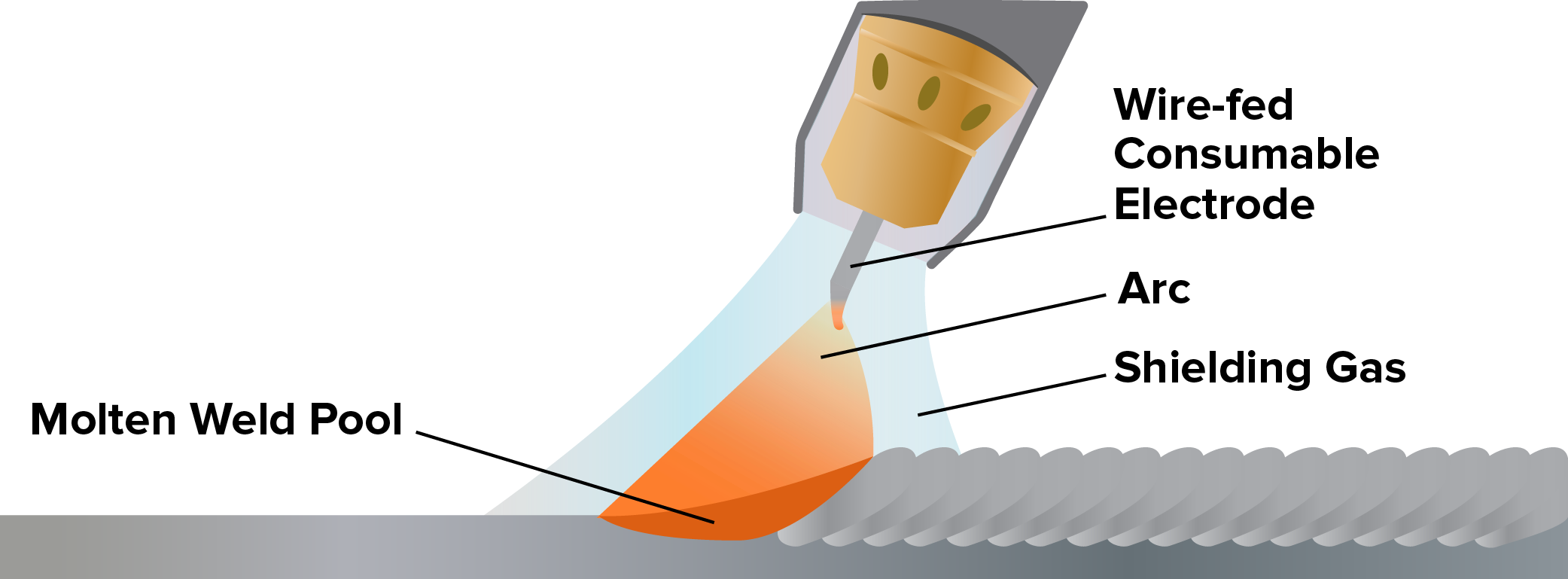

Gas metal arc welding gmaw sometimes referred to by its subtypes metal inert gas mig welding or metal active gas mag welding is a welding process in which an electric arc forms between a consumable mig wire electrode and the workpiece metals which heats the workpiece metals causing them to melt and join. The selector switch was stuck at max current and it randomly produced too little welding current. Usaweld replacement parts for the miller m 25 mig welding gun used on the following miller mig welders. Lincoln welder wiring diagram.

Mig welder wiring diagram welcome to my website this blog post will review regarding mig welder wiring diagram. The metal transfer in mig welding takes place in four primary ways and these are globular short circuiting spray and pulsed spray. 210 212 212 wautoset 250 sn kf851979 and up 250x 251 252 the picture shows the oem mig gun parts for the welder you selectedhowever a mig welding gun other than the oem mig gun may be installed on your machine. From safety precautions operationssetup information and maintenance to troubleshooting and parts lists millers manuals provide detailed answers to your product questions.

The trusty 32 year old mig welder urgently needed some work. Mig welding also known as gmaw is a really popular type of welding thats frequently used for welding low alloy steels and is well suited for welding autobody parts and home repair projects. Along with the wire electrode a shielding gas feeds through the welding gun. We have actually gathered numerous photos with any luck this photo is useful for you as well as help you in finding the solution you are trying to find.

This means that the welder still requires skill but that the mig welding machine will continuously keep filling the joint being welded and electrodes do not need to be changed out between welds. Find replacement parts and get the most from your miller products by downloading the specific owners manual for your unit. Mig welding is an abbreviation for metal inert gas welding.