Piping Layout Guide

This presentation covers various aspects of piping engineering like.

Piping layout guide. Following points shall be adhered to for optimum pipe routing. Since all safe work operations must begin with preplanning the field engineer makes a direct contribution to safety by reviewing the planned work with safety in mind. This book fills a training void with complete and practical understanding of the requirements and procedures for producing a safe economical operable and maintainable process facility. When heat tracing is used to ensure that the system functions from a process standpoint regardless of climate conditions it is known as process.

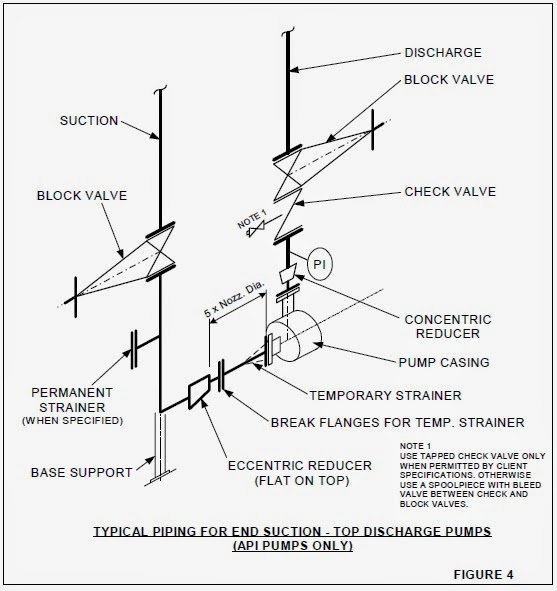

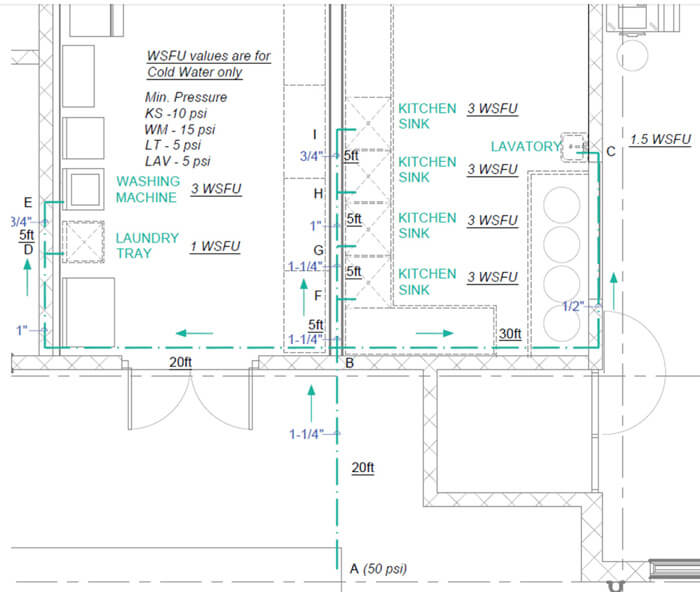

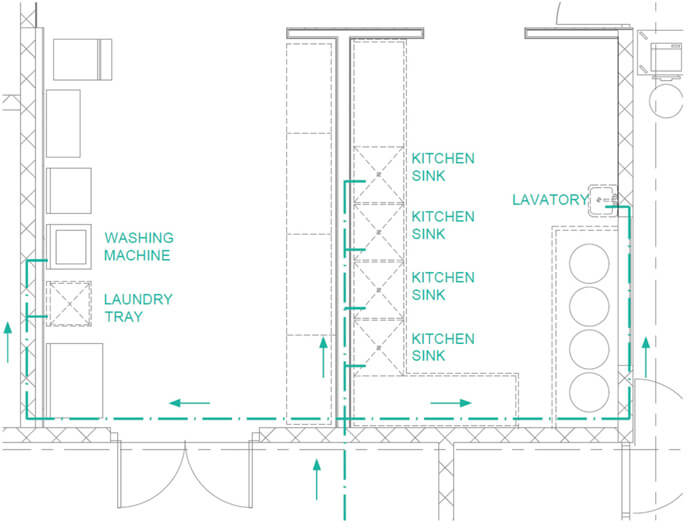

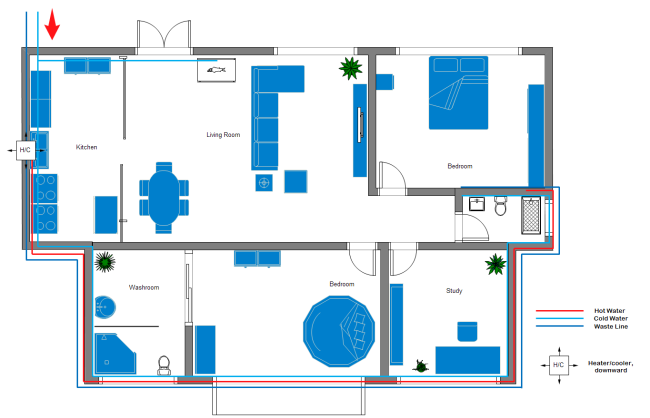

This presentation covers the basics points of piping which are meant for those persons who are first time entering our epc industry. A preliminary piping layout study layout shall be made to determine the requirement of spacing between pumps especially in case of side suction side discharge top suction top discharge pumps where straight length requirement platform cps requirement etc have to be considered. Piping layout must be carried out with process requirements economy orderliness stress and supporting requirements in mind. Piping systems are available with liners of varying type and thickness with molded fabricated or filament wound fittings ranging in size from 1 to 7225 to 1800 mm.

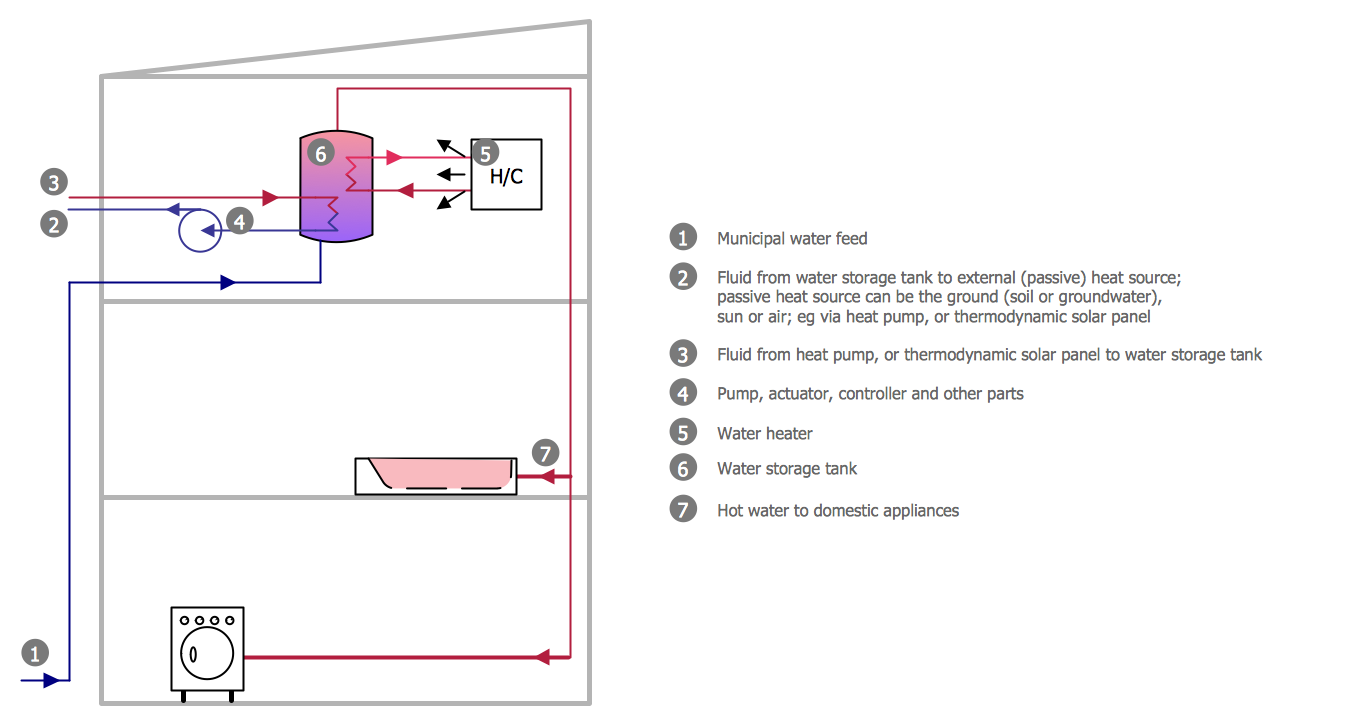

Heat tracing of piping systems heat tracing is a generalized term relating to the application of radiant heat input to piping systems from tubing attached to the outside of the pipe. Function of piping engineering piping engineering team plant layout. To provide the layout designer guidelines for developing pump piping designs that fully consider safety operation maintenance and economics. Piping shall be arranged in an orderly manner and routed as directly as practical preferably in established banks or pipeways.

It is intended to aid in the process of engineering specification and design of industrial plastic piping systems using the family of asahi plastic piping systems. The engineers guide to plant layout and piping design for the oil and gas industries gives pipeline engineers and plant managers a critical real world reference to design manage and implement safe and effective plants and piping systems for todays operations. Asahiamerica is proud to present this engineering design guide to you. Valve classification based on function.

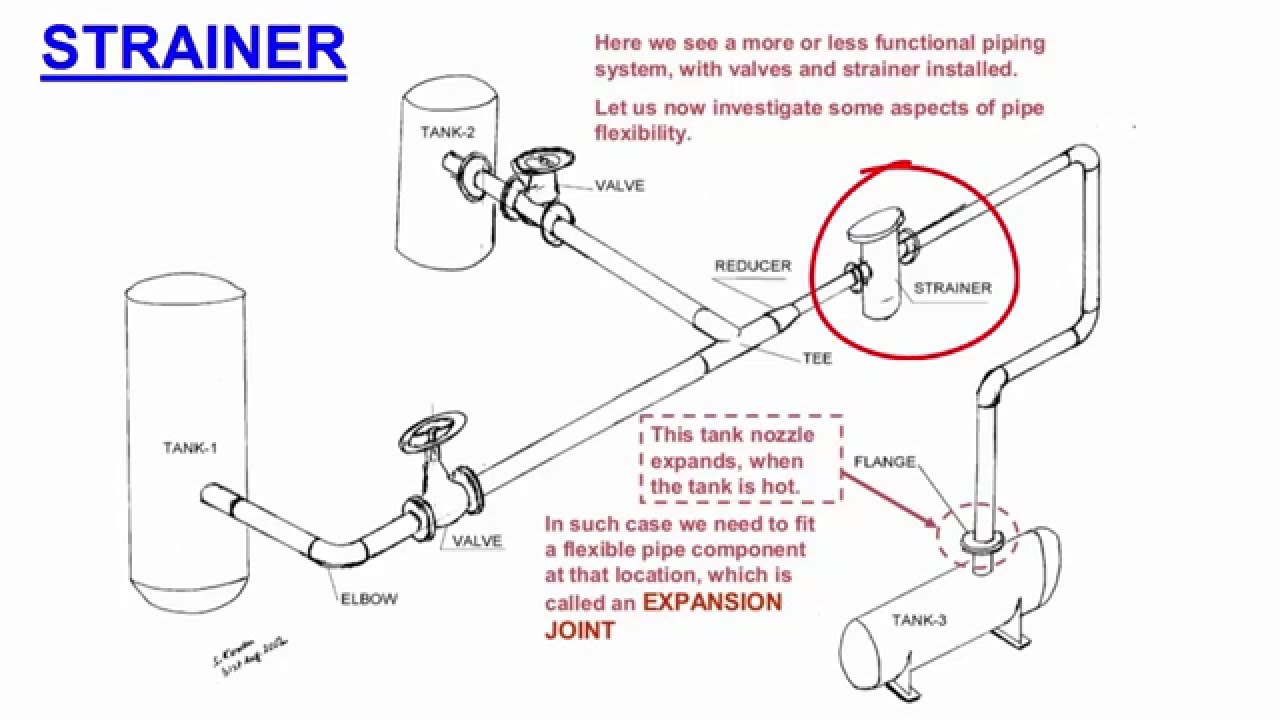

The piping or mechanical field engineer is a direct contributor to the safety of the work operations at the construction site. Pipe fittings classification.