Process Fmea Worksheet

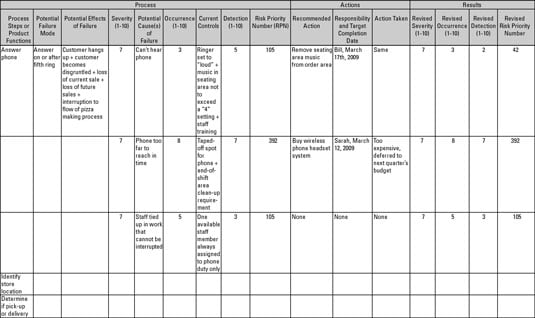

Fmea worksheet sev occ det rpn what are the existing controls that either prevent the failure mode from occurring or detect it should it occur.

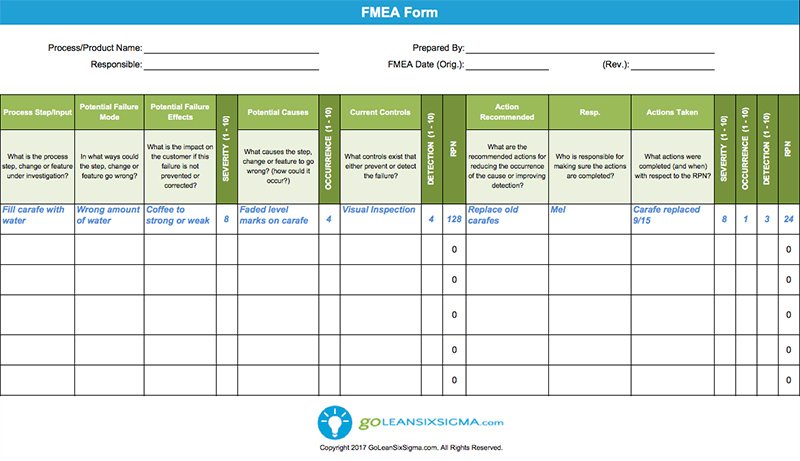

Process fmea worksheet. Customize the severity occurrence and detection ranking scales. Create an rpn risk priority number and rank the failure modes. Define the scope of a pfmea. Use the fmea analysis worksheet to document the results of the study.

Ideally the fmea is formed at the beginning of the design of the product or service and used throughout its lifetime. Pfmea is a methodical approach used for identifying risks on process changes. It is used in the ongoing process for control of the product project. Explain the methodology of the fmea process.

Assess the risk of the failure severity occurrences and detection. Healthcare fmea hfmea process steps 1 and 2 process steps worksheets hfmea worksheets healthcare fmea process steps 1 and 2 healthcare fmea worksheets description worksheets for the healthcare fmea process steps 1 and 2. Fmea stands for failure mode and effects analysis the fmea a is a structured methodology used by business to help capture and evaluate risk and then monitor the success of mitigation actions ideally improving the process by removing the opportunity for failure. This training enables learners to.

Potential failure mode potential failure effects potential causes current process controls actions recommended responsibility target date actions. It is designed to help prevent failure. Fmea examples also document current knowledge of the risks and actions for continuous upgrading of the product. Identify all failure modes.

Work though each step of conducting a pfmea. Process fmea analysis is at the manufacturingassembly process level. Consider the root causes. Assemble an fmea team.

The basic steps to using the fmea worksheet are. In what ways can the step go wrong. What is the step. The process fmea initially identifies process functions failure modes their effects on the process.

Explain the methodology of the fmea process. If there are design inputs or special characteristics the effect on end user is also included. Assemble an fmea team. The focus is on manufacturing related deficiencies with emphasis on improving the manufacturing process ensuring the product is built to design requirements in a safe manner with minimal downtime scrap and rework.

Use the fmea analysis worksheet to document the results of the study. Define the scope of a pfmea.

.png)