Welding Certification Levels

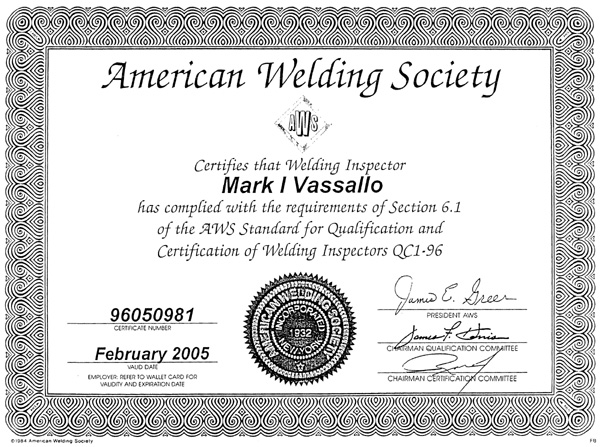

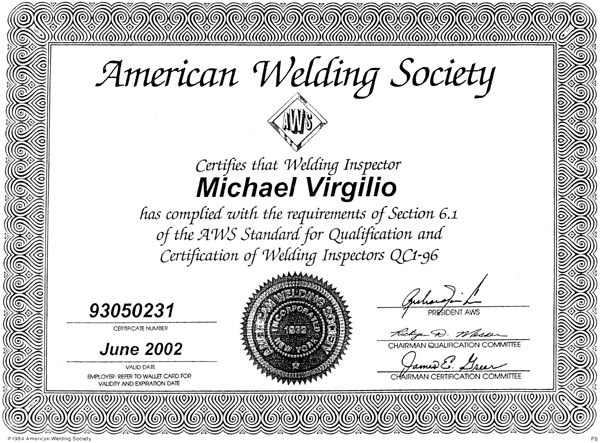

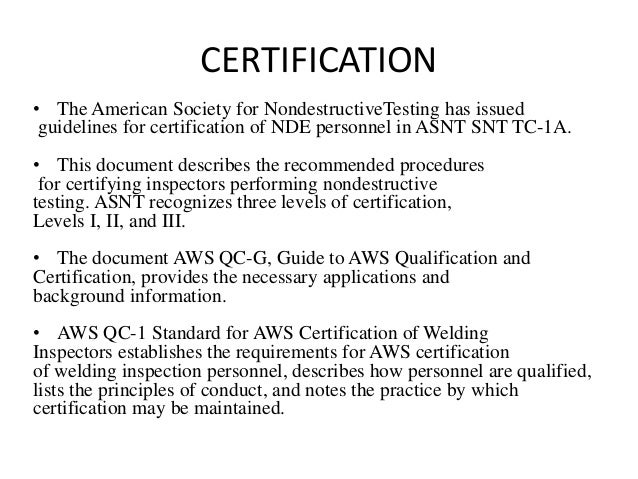

Aws offers nine different certification categories from inspectors supervisors and educators to radiographic interpreters welding engineers and fabricators.

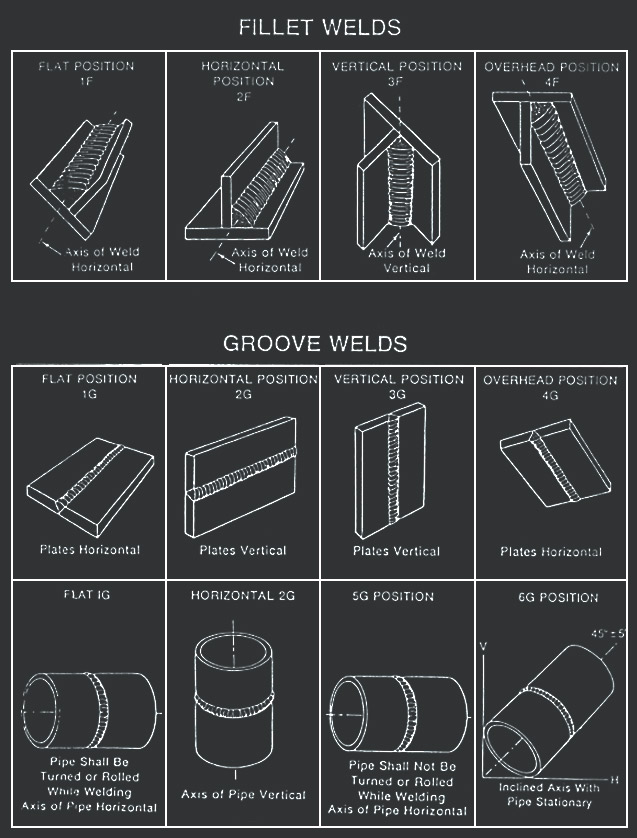

Welding certification levels. Certified welding inspector program. The highest level for them is usually 6g which means they can weld 360 degrees around a pipe that doesnt move. Endorsements are defined in aws qc1 as the approval of an additional skill documented in writing and added to a certification credential. As the authorized national body for the international institute of welding iiw the cwb group is able to provide several levels of internationally recognized certification and qualification for welding companies interested in being certified to iiws implementation of iso 3834.

The extent of certification is described by a number of variables which include the specific welding process type of deposited metal thickness joint design position backing and others. Weld the metals given by the welding inspector in the position the test is designed for by following the instructions provided. This opens up opportunities for more money leadership roles and higher level career challenges. How to oversee welders to ensure that higher level work.

And the complementary factors that help maximize productivity. Cwi certification can lead you to a career that is stable engaging and fulfilling on all levels. From associate certification to senior level credentials most welders find career expansion as an inspection professional to be both rewarding and lucrative. The main part of the welders test consists of welding one or more test coupons which are then examined using non destructive and destructive methods.

Welder certification is based on specially designed tests to determine a welders skill and ability to deposit sound weld metal. One of the best ways to advance your welding career is by earning a specialized certification. Producing this weld to the satisfaction of a certified welding inspector is tough sledding for a beginner. Cut the metal welded according to the instructions and prepare them for a bend test or some approved form of quality testing.

It is a procedure to determine if the applicant for certification has the skill level required to perform the designated tasks. Certifications verify that the welder is familiar with codes specific to the required work and can perform in compliance with those codes. The very basics of a welding welding certification are. Welding certification is offered by several different welding organizations.

Welding supervisors are valued in every industry that uses welding as a core process in the manufacture construction or fabrication of their products. Nevertheless a 6g certification is considered the gold standard of the welding profession.