Alternator Welder Wiring Diagram

Bailey line road 113161 views.

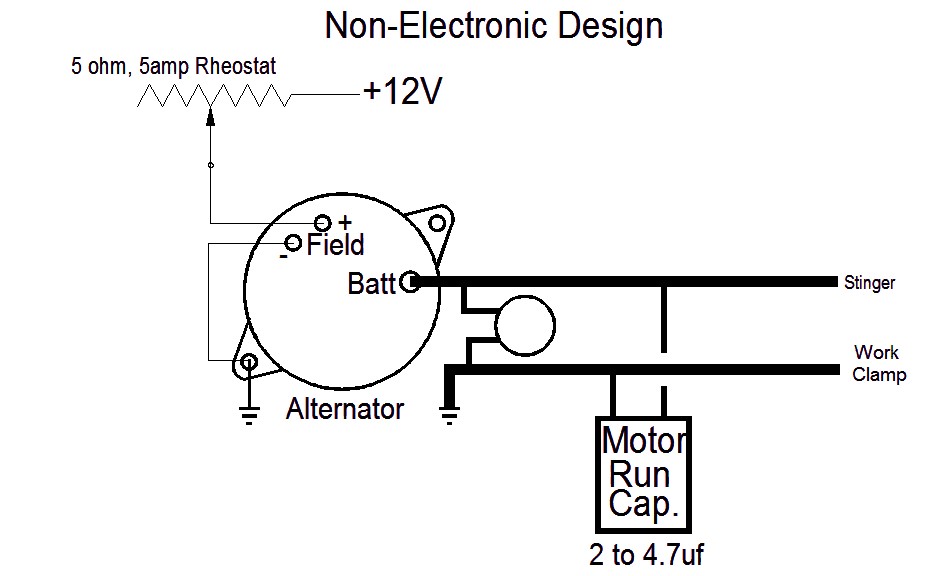

Alternator welder wiring diagram. This should be 10 to 12 feet long. The premier power welder is the only onboard welding system with a proven track record since 1979. Variety of lincoln 225 arc welder wiring diagram. I didnt have anybody to teach me so i bought a couple of books borrowed a 110v lincoln weldpac wire feed welder and set out to.

Electrical knowledge helps but is not critical. Cut a piece of 4 gauge wire to use as a welding lead. Forming 4 is a schematic view of welding the elongated stator body with a welding. Strip both ends with a wire stripper.

Onboard welder using a gm delco 140 amp alternator introduction i learned how to weld out of necessity when i needed to fabricate a rear bumper that can accommodate tow points. A wiring diagram is a simplified conventional pictorial depiction of an electric circuit. It sounds like there is a way to wire the alternator to put out ac power to run lights drills etc. Our system offers battery charging welding and a 115 vold dc power source.

Choosing a backup generator plus 3 legal house connection options transfer switch and more duration. How to make alternator welders by contributor. Fog light wiring diagram with relay. Welding begins just above idle.

Wire alternator wiring diagram. Electric motor electric cars electrical installation electrical wiring engine repair car engine trailer wiring diagram vw t3 syncro mechanical engineering. Connect the other end to the welding electrode holder. It shows the elements of the circuit as streamlined shapes as well as the power as well as signal links between the gadgets.

Connect one end of the wire to the output terminal bolt of the alternator. A gas or electric motor. I am not an engineer. Tighten it with a wrench.

See photos of our premier power welder installed in various vehicles jeeps trucks tractors. I believe the alternator in its stock config puts out dc power. Dc welder using automotive alternator acdc tig and mig add on for standard engine driven it is. The current streamlined control box is our 3rd generation with few switches and easy operation.

The main components for stick welding are. You will need to be mechanically inclined. 12hp or better for gas 10hp for electric. A method of manufacturing a stator of an alternator comprising the steps of.

What does it take to build your own welder. A 120 amp or larger alternator that can be easily modified for an external regulator. See photos of our premier power welder installed in various vehicles jeeps trucks tractors.