Oven Piping Diagram

In some models the wiring diagram may be contained in an envelope inside the console.

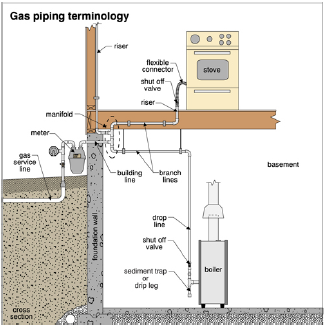

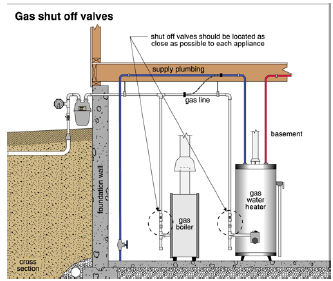

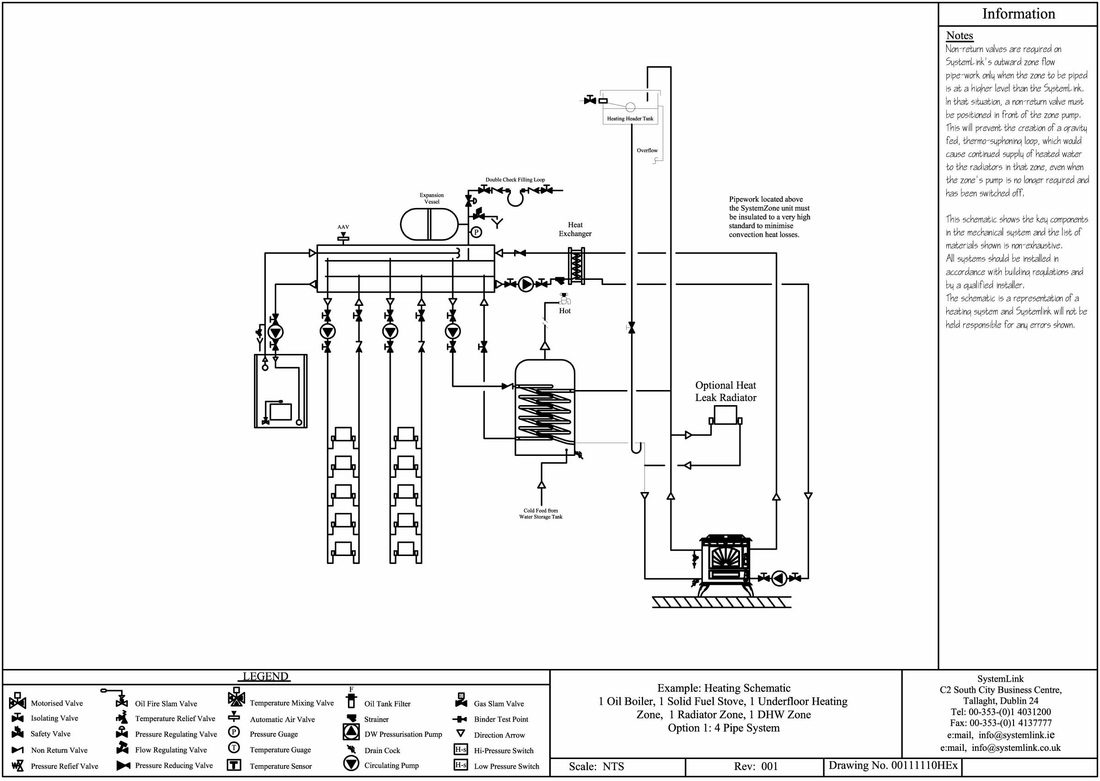

Oven piping diagram. Steam vertical coil piping diagram control valve 5 psig min steam vacuum breaker check valve to condensate return gravity drain 18 min. The vacuum pump should have a back current prevention valve attached. The terminal block is where the main power cord attaches to the oven circuitry. In the process industry a standard set of symbols is used to prepare drawings of processes.

The first tray will use product key 1 and will be placed in rack position 2. Where a fan is essential to the operation of the oven fan operation shall be proved and interlocked into the safety circuitry. Two trays of product are going to be cooked in the oven at. If the mixture in the flashtube has too much gas too rich or has too much air too lean the burner will not light.

Also check the terminal block for problems as described below. Therefore 38 40 standard 44 46 deep cubic feet. Click on the vintage parts link to access the vintage parts home page. Appropriate vacuum pumps for the ovens and the necessary plumbing parts for connecting are listed in the table below.

A diagram which shows the interconnection of process equipment and the instrumentation used to control the process. You may find it available at vintage parts. The main burner or surface unit controls and oven thermostat are usually located at the front of the cooktop area and selector switches or lighting controls may be located in the console area at the rear of the cooktop. A piping and instrumentation diagram pid is defined by the institute of instrumentation and control as follows.

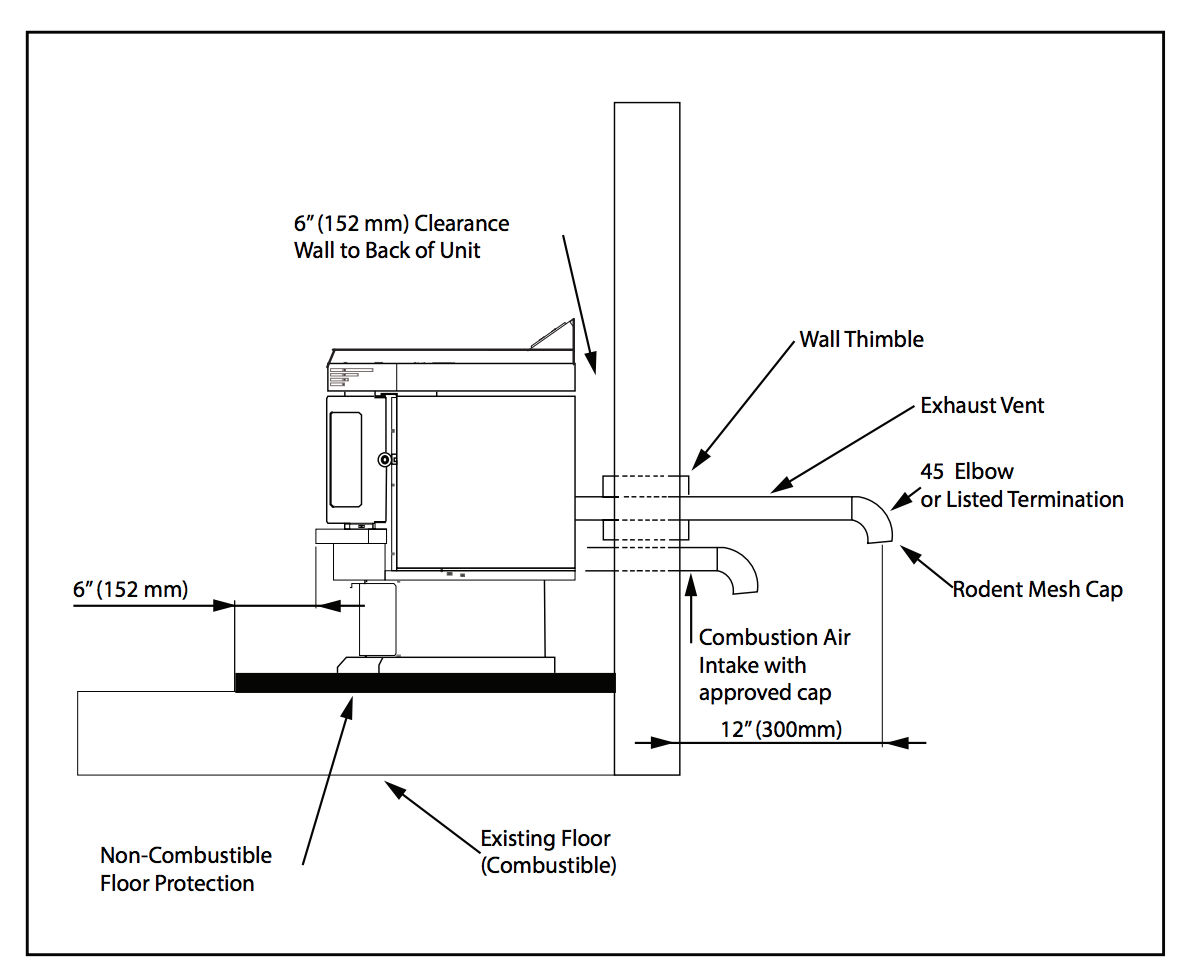

When the mixture travels down the tube to point of ignition the flame will carry back from the lighter to the charge port and light the gas at the burner. Steam horizontal coil piping diagram note 1. Oven stove range and cooktop repair. Installation and operation of 613 e series gas fired convection oven 6 d.

See figure 4 e in some installations the electric oven or electric stove is wired directly into the house wiring. Connecting a vacuum pump. Vacuum breakers and air vents should be piped to a drain or other suitable location where discharged steam cannot lead to personal injury. The second tray will use product key 6 and will be placed in rack position 4.

It will be just inside the back somewhere. This part is no longer available through the hobart smartparts estore. Once the oven display indicates load. Referring to this table select an appropriate vacuum pump with the necessary plumbing parts.